In the world of electronics and connectivity, the significance of cable wire harness assembly cannot be overstated. Proper assembly techniques are crucial for ensuring optimal performance and enhanced reliability in various applications, from automotive to aerospace. As renowned industry expert Dr. Robert Thompson points out, “The key to a successful cable wire harness assembly lies in meticulous planning and attention to detail.” This perspective underscores the importance of following best practices in the assembly process to mitigate risks associated with electrical failures.

As the demand for more complex and sophisticated electronic systems continues to rise, the need for high-quality cable wire harness assembly becomes even more vital. Engineers and technicians must adopt innovative approaches that not only improve efficiency but also guarantee that the assembled harnesses can withstand environmental stresses and provide long-lasting performance. By embracing new technologies and methodologies, the industry can pave the way for advancements that will drive reliability and performance in cable wire harness solutions.

In conclusion, mastering cable wire harness assembly is essential for any professional in the field. It involves understanding the intricacies of design, material selection, and assembly techniques. As we delve deeper into the best practices for assembling cable wire harnesses, we aim to equip individuals and organizations with the knowledge needed to achieve superior outcomes in their electrical systems.

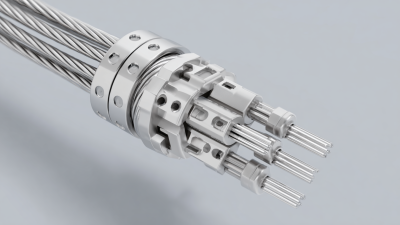

In modern applications, the importance of cable wire harnesses cannot be overstated. These components serve as a critical nexus for power and data distribution in an array of industries, from automotive to aerospace and beyond. According to a report by Allied Market Research, the global market for cable assemblies is projected to reach $181.4 billion by 2027, reflecting a compound annual growth rate (CAGR) of 6.2% from 2020. This growth is indicative of the increasing complexity of electronic systems and the demand for reliable connections that cable wire harnesses offer.

Cable wire harnesses enhance performance and reliability by organizing multiple wires into a single assembly, thus reducing the hassle of installation and minimizing error due to miswiring. Furthermore, well-designed harnesses contribute to the durability of electronic systems by shielding wires from environmental factors, mechanical strain, and electromagnetic interference. The National Electrical Manufacturers Association (NEMA) emphasizes that the proper selection and assembly of cable harnesses can prevent costly failures and downtime, ultimately extending the service life of the entire system. As industries move towards greater automation and connectivity, the role of high-quality wire harnesses will continue to be pivotal in ensuring operational excellence and safety in various applications.

When assembling a cable wire harness, selecting the right materials and tools is essential for achieving optimal performance and reliability. The primary components of a wire harness include wires, connectors, insulation materials, and protective coverings. Wires should be chosen based on their gauge and insulation type, which must be suitable for the application's electrical and environmental demands. Additionally, connectors must be compatible with the wires and capable of sustaining the required voltage and current levels. Employing high-quality insulation materials can prevent electrical interference and enhance durability.

For efficient assembly, several tools are indispensable. Wire strippers and crimping tools are necessary for preparing wires and securing connectors. A heat gun may be required for applying heat-shrink tubing, which provides added protection and a tidy finish to connections. Furthermore, a cable tie gun can help manage and organize the harness, ensuring that the wires are bundled neatly and securely. Using these materials and tools effectively will streamline the assembly process, minimize errors, and enhance the overall performance and longevity of the cable wire harness.

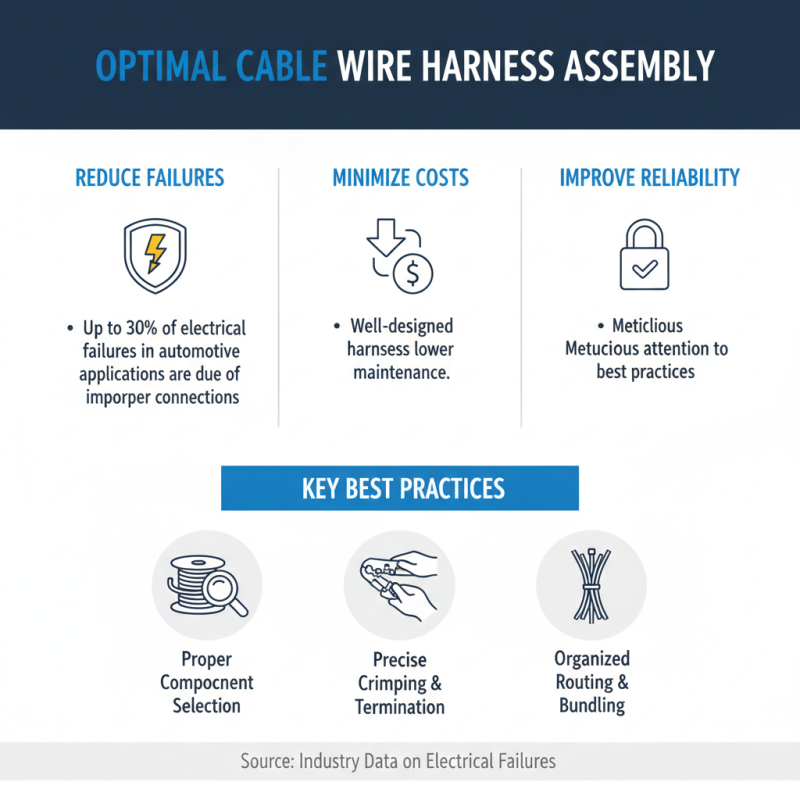

When assembling a cable wire harness, attention to detail throughout each step is essential for ensuring optimal performance and reliability. A well-assembled harness not only minimizes the risk of electrical failures but also contributes significantly to the longevity of the equipment it supports. According to industry reports, up to 30% of equipment failures in industrial environments can be traced back to poor wiring practices. Hence, following a step-by-step process during assembly is crucial.

The assembly process should begin with a thorough design review, ensuring that the specifications align with the intended application. Utilizing appropriate wire types, connectors, and insulation materials is critical; for instance, reports suggest that harnesses constructed with high-quality, heat-resistant materials can withstand temperatures as high as 125°C, improving their reliability in demanding environments. Following this, accurate cutting, stripping, and crimping of wires must be performed meticulously to avoid issues such as weak connections or short circuits.

Finally, securing the harness with proper mounting techniques prevents movement-related wear over time, reducing the possibility of failure. Implementing robust testing procedures post-assembly, including continuity and insulation resistance tests, further validates the reliability of the harness. By adhering to these steps, manufacturers can significantly enhance the operational performance and lifespan of their products, aligning with industry standards which indicate that well-assembled harnesses can increase system reliability by up to 40%.

When assembling a cable wire harness, ensuring optimal performance and reliability necessitates meticulous attention to best practices. A well-designed wire harness can reduce the risk of failures and minimize maintenance costs over time. According to industry data, improper connections and assembly techniques are responsible for up to 30% of electrical failures in automotive applications, highlighting the critical nature of following proper procedures.

One of the keys to achieving optimal performance is the use of appropriate materials. Selecting the right gauge of wire, insulation type, and connectors based on the specific application requirements can significantly impact the harness’s functionality and lifespan. It's crucial to consider factors such as temperature ratings, environmental exposure, and the electrical load that the harness will carry. Additionally, maintaining proper cable routing minimizes stress and wear on the assemblies, which is vital for prolonged reliability.

Tips: Always double-check that all connections are secure and free of corrosion before finalizing the assembly. Utilizing strain relief methods, such as cable ties or clamps, can help alleviate stress on the wire connections and increase the durability of the harness. Regular testing and inspection of wire harnesses during and after installation will further ensure that they operate at peak performance levels, mitigating potential issues before they escalate.

Maintaining a cable wire harness for optimal performance and reliability is crucial in various industries, including aerospace, automotive, and telecommunications. According to a report from the Wiring Harness Manufacturers Association, approximately 60% of electrical failures are attributed to poor harness maintenance. Regular inspection and testing are vital in identifying potential issues before they affect performance. Techniques such as visual inspections, continuity testing, and insulation resistance testing can help ensure that connectors, terminals, and insulation materials remain intact and functional.

In addition to routine inspections, proper cleaning and environmental protection are paramount to prolonging the lifespan of cable wire harnesses. Contaminants such as dust, moisture, and chemical exposure can degrade materials and compromise performance. Adopting proper sealing mechanisms and protective coatings can significantly reduce the risk of damage, as noted in findings from the International Electrotechnical Commission. Moreover, employing advanced testing methodologies, such as thermal imaging and tensile strength tests, can help assess the overall condition and integrity of the harness, ensuring it meets industry standards for reliability and efficacy in demanding applications. By implementing these maintenance and testing techniques, organizations can enhance the durability of their cable wire harnesses, reducing failures and downtime.

| Aspect | Details | Frequency |

|---|---|---|

| Visual Inspection | Check for physical damage, fraying, and loose connections. | Monthly |

| Functional Testing | Test electrical connections for continuity and resistance. | Every 3 months |

| Environmental Checks | Assess for exposure to moisture, chemicals, or extreme temperatures. | Biannually |

| Connector Testing | Ensure pins and sockets are free from corrosion and secure. | Annually |

| Repair Procedures | Document steps for replacing damaged wires or connectors. | As Needed |

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681