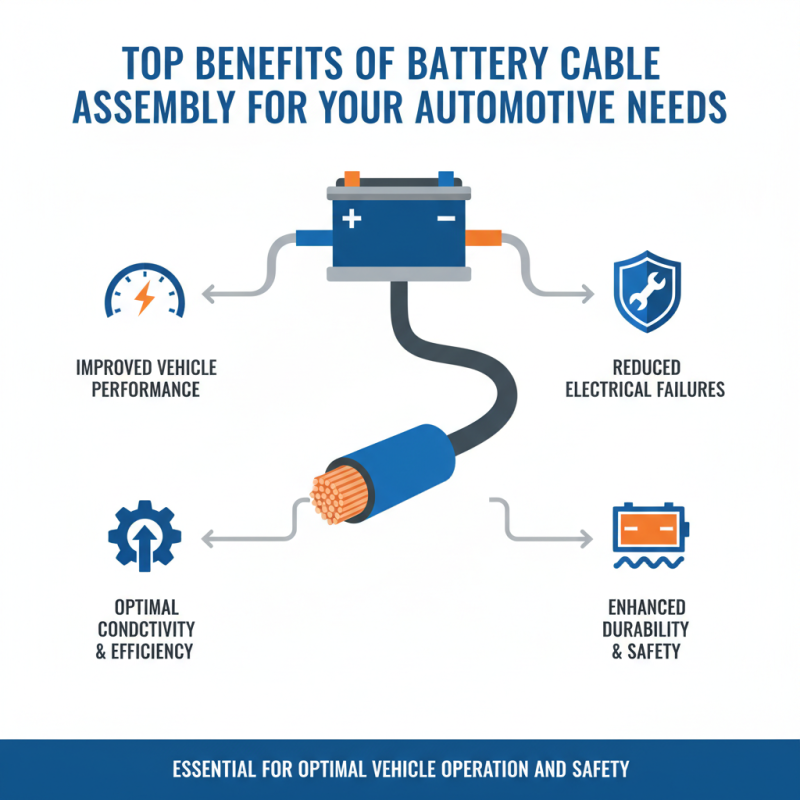

When it comes to automotive performance, the importance of components that ensure efficient electrical connectivity cannot be overstated. Among these components, battery cable assemblies play a pivotal role in supporting the overall functionality and reliability of vehicles. A well-designed battery cable assembly not only facilitates the transfer of electrical current from the battery to various automobile systems but also enhances the durability and safety of the electrical circuits.

The benefits of utilizing high-quality battery cable assemblies extend to improved vehicle performance and reduced risk of electrical failures. By providing optimal conductivity, these assemblies minimize power losses and enable the vehicle to operate at its peak efficiency. Additionally, robust battery cable assemblies are engineered to withstand harsh environments, ensuring longevity and dependability even under extreme conditions. With advancements in technology and materials, the modern battery cable assembly is designed to meet the stringent demands of today’s automotive applications.

In summary, incorporating reliable battery cable assemblies into automotive systems is not just a matter of convenience; it is essential for optimal vehicle operation and safety. As vehicle technology continues to evolve, investing in quality battery cable assemblies becomes increasingly critical for both performance enthusiasts and everyday drivers alike.

Battery cable assembly is a crucial component in automotive applications, ensuring reliable power distribution from the battery to various electrical systems in a vehicle. It consists of a network of cables, connectors, and terminals that work in unison to transmit electrical energy efficiently. Properly designed and assembled battery cables can significantly enhance the performance and longevity of a vehicle's electrical system, minimizing the risk of failure and ensuring safe operation.

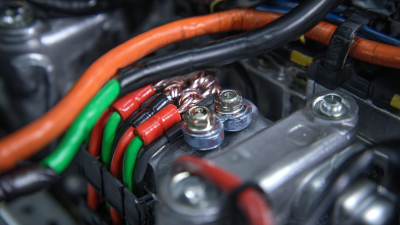

When considering battery cable assembly for automotive needs, it is essential to understand the materials and specifications involved. High-quality copper or aluminum cables are favored for their conductivity and durability, while the choice of connectors can influence the connection's reliability. It’s important to ensure that the gauge of the wire is appropriate for the vehicle's power requirements to prevent overheating or voltage drops.

Tips: Always choose cables with adequate insulation to protect against environmental factors such as moisture and heat. Additionally, regularly inspect the battery cables for signs of wear, corrosion, or loose connections, as these issues can lead to performance problems. Proper cable routing and securing can also help prevent damage during operation, enhancing the overall efficiency of your vehicle's electrical system.

When it comes to automotive systems, the quality of battery cable assemblies plays a crucial role in ensuring optimal performance and reliability. Quality battery cable assemblies are designed to handle the demanding electrical loads of modern vehicles, which require efficient power transfer for advanced features such as start-stop systems and electric power steering. According to industry reports, a significant percentage of electrical failures in vehicles can be attributed to poor-quality connections and wiring, making the choice of battery cables paramount.

One of the key advantages of using quality battery cable assemblies is their enhanced conductivity. High-quality materials such as copper or tinned copper are commonly used in their construction, providing lower electrical resistance and improved durability. This can lead to a decrease in voltage drop, thereby ensuring that electrical components receive sufficient power. Moreover, quality assemblies are often built to withstand extreme temperature variations and vibrations, which are prevalent in automotive environments. Reports indicate that using superior battery cables can decrease the incidence of electrical system malfunctions by up to 30%, significantly enhancing vehicle reliability and performance.

Additionally, quality battery cable assemblies contribute to safety. Properly insulated and assembled cables reduce the risk of short circuits and electrical fires, which can have catastrophic consequences in automotive settings. Recent studies highlight that addressing electrical system failures proactively through investment in quality components could lead to cost savings in repairs and replacement parts down the line, with estimates suggesting that such measures can save vehicle owners as much as 40% in unexpected maintenance costs annually. Thus, opting for high-quality battery cable assemblies not only improves vehicle efficiency and durability but also ensures a safer driving experience.

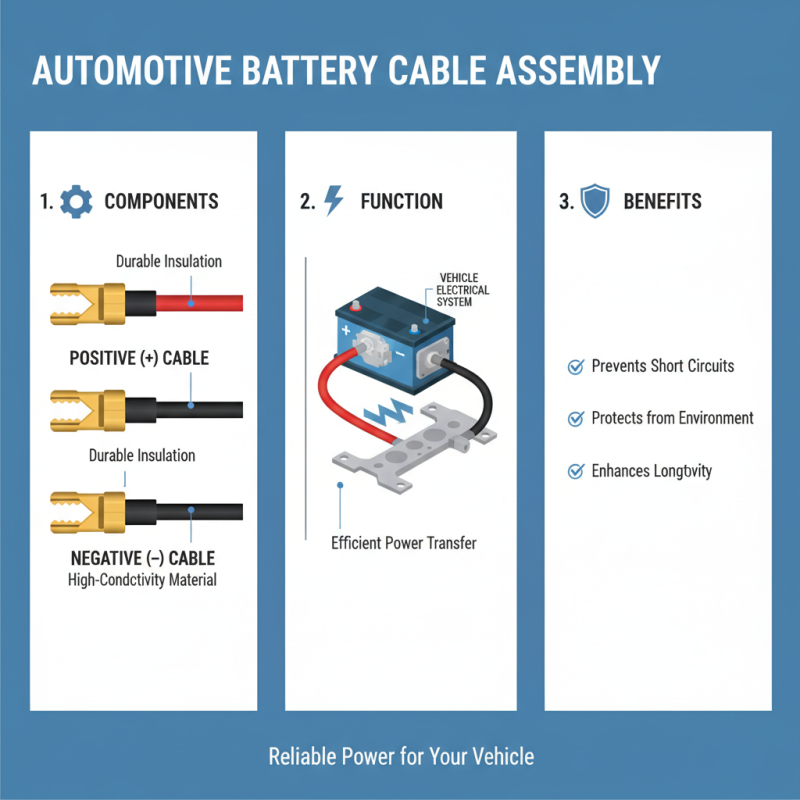

The assembly of battery cables in automotive applications is a crucial process that involves several essential components. At the heart of this assembly are positive and negative battery cables, which are constructed from high-conductivity materials to ensure efficient power transfer between the battery and the vehicle's electrical system. These cables typically come with durable insulation to prevent short circuits and protect against environmental factors, thereby enhancing their longevity.

In addition to the cables, terminal connectors play a significant role in battery cable assembly. These connectors are designed to provide secure and reliable connections between the battery and the vehicle’s systems. They are often made from corrosion-resistant materials to withstand the rigorous conditions of the automotive environment. Furthermore, heat shrink tubing and cable clamps are used to ensure proper organization and protection of the cables, minimizing the risk of damage due to friction or exposure to the elements. Overall, understanding the components involved in battery cable assembly is essential for optimizing automotive performance and reliability.

When it comes to battery cable assemblies, several key factors influence their overall performance in automotive applications. One primary factor is the material used for the cables themselves. High-quality, conductive materials such as copper ensure minimal resistance and effective power transmission between the battery and the vehicle’s electrical systems. The gauge of the wire also plays a crucial role; thicker cables can carry more current without overheating, which is essential for the reliable operation of high-performance vehicles.

Another important aspect affecting performance is the connector design and its compatibility with the battery terminals and other components. Properly designed connectors contribute to a secure and efficient connection, minimizing the risk of short circuits or voltage drops that can lead to diminished functionality. Additionally, the manufacturing process, including techniques like crimping and insulation, ensures durability and resistance to environmental factors, such as moisture and temperature variations. These considerations are vital for ensuring that battery cable assemblies meet the rigorous demands of modern automotive applications.

Maintaining the lifespan of your battery cable assembly is crucial for optimal automotive performance. Regular inspections play an essential role in this process. Start by visually checking the cables for any signs of wear or corrosion. This can include fraying wires, cracked insulation, or rust around the terminals. Keeping the terminals clean and free of corrosion significantly improves the electrical connection and helps prevent potential issues down the line. Using a mixture of baking soda and water can effectively neutralize corrosion if it is present.

Another important aspect of maintenance is ensuring that the cables are properly secured. Loose cables can lead to a poor connection, which may result in vehicle starting issues or electrical malfunctions. Tightening any loose connections and ensuring that all mounting hardware is secure will help maintain stability and performance. Additionally, it’s advisable to keep the battery area dry and free of any excessive moisture, as this can contribute to corrosion and degradation of the cables.

By following these maintenance tips, vehicle owners can significantly prolong the life of their battery cable assemblies, ensuring that they remain reliable components of their automotive systems.

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681