In today's rapidly advancing technological landscape, choosing the right cable assembly power solutions is essential for the success of any project. Cable assembly power systems play a vital role in connecting various electrical components, ensuring efficiency and reliability in power distribution. These assemblies are integral in various applications, from consumer electronics to industrial machines, and can significantly impact the overall performance and safety of a system.

Selecting the appropriate cable assembly power solution involves careful consideration of multiple factors, including the specific technical requirements, environmental conditions, and potential future needs of a project. Understanding the intricacies of different cable types, connectors, and assembly methods is crucial for making informed decisions that will enhance reliability and performance. By fully grasping these considerations, project managers and engineers can better navigate the complexities of cable assembly power choices, leading to optimized designs that meet the unique demands of each project.

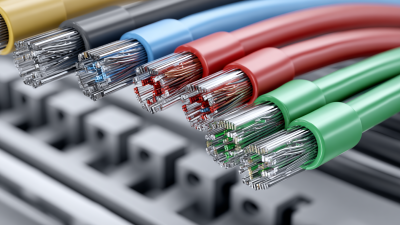

When embarking on a project that requires power solutions, understanding cable assembly power solutions is crucial. Cable assemblies serve as the backbone of electrical connections, facilitating power delivery and signal transmission. Each assembly is designed with specific functions in mind, making it essential to assess the unique requirements of your project. Factors such as voltage levels, current ratings, environmental conditions, and mechanical stresses must be carefully considered to ensure the appropriate performance and reliability.

Another important aspect of understanding cable assembly power solutions is recognizing the materials and construction methods used in their production. The insulation, conductor type, and connector options can significantly influence the efficacy and longevity of the assembly. By evaluating the intended application and operational environment, you can make informed decisions that align with industry standards and safety regulations. This deep understanding of cable assembly solutions will ultimately help you optimize performance, reduce downtime, and enhance the overall success of your project.

| Criteria | Description | Importance Level |

|---|---|---|

| Voltage Rating | The maximum voltage the cable can handle without degrading. | High |

| Current Rating | The maximum current that can flow through the cable safely. | High |

| Temperature Range | Operating temperature limits for the cable. | Medium |

| Cable Length | The length of the cable is critical for the application. | Medium |

| Shielding Type | Specifies if the cable needs to be shielded to protect against interference. | Low |

| Connector Type | The type of connectors that will be used at the ends of the cable. | High |

| Compliance Standards | Standards that need to be met for safety and performance. | Medium |

| Cost | The overall cost of the cable assembly solution. | High |

Identifying the power requirements of your project is a crucial first step in selecting the right cable assembly power solutions. To begin, you must assess the voltage and current specifications needed for the components within your project. Different applications may demand varying voltage levels, so clearly defining these needs will help streamline the selection process. It’s also important to consider the maximum current draw to avoid potential overloads or performance issues, as insufficient power can lead to malfunction or inefficiency.

Additionally, it’s advisable to evaluate the environmental conditions in which the cable assembly will operate. For instance, factors such as temperature extremes, moisture, and exposure to chemicals can impact the performance and reliability of the power solutions you choose. By understanding the operating environment, you can select materials and designs that enhance durability and ensure safe operation. Moreover, recognizing any future scalability or modifications in your project can influence the specifications you require, ensuring that your cable assemblies can accommodate growth without requiring complete redesign.

When evaluating different types of cable assemblies for power solutions, it's essential to consider specific parameters that will affect the performance and reliability of your projects. According to the latest industry data from the Wiring Harness Manufacturers Association (WHMA), over 70% of electrical failures in assemblies can be traced back to improper design and selection processes. This highlights the importance of thorough evaluation when choosing cable assemblies.

The most common types of cable assemblies include custom-built, off-the-shelf, and shielded options. Custom-built assemblies offer tailored specifications that meet unique project requirements, often delivering the highest performance and reliability. In contrast, off-the-shelf assemblies provide quick solutions with less lead time, but they may not always meet specific project needs. Meanwhile, shielded cable assemblies are crucial in environments with high electromagnetic interference (EMI), helping to protect the signals and maintain integrity. According to market reports, the demand for shielded cable assemblies has increased by approximately 15% annually as industries recognize the growing need for reliable power distribution in complex applications.

When assessing these types of cable assemblies, it's crucial to consider factors such as material quality, assembly processes, and testing standards. Industry reports indicate that assemblies that undergo rigorous testing are up to 40% less likely to fail during their lifespan. By prioritizing quality and evaluating the types available, project managers can ensure that their power solutions are not only efficient but also durable and reliable.

When selecting cable assembly power solutions for your projects, assessing compatibility with existing systems is crucial. A thorough evaluation ensures that the new cable assemblies integrate seamlessly with the existing hardware, preventing potential failures or inefficiencies. Begin by examining the specifications of the current systems, including voltage, current ratings, and connector types. This information will guide you in selecting assemblies that match or exceed these requirements, ensuring reliable performance.

Tips: Before making a purchase, create a checklist of compatibility factors such as cable length, shielding requirements, and environmental conditions. This not only simplifies your selection process but also helps avoid costly mistakes. Additionally, it’s wise to consult with engineers or technical experts who have experience with similar systems to gain insights into potential challenges you may face.

Moreover, consider future expansions during your assessment. While your current project might require a specific set of standards, anticipating future needs can save time and resources down the line. Opt for cable assemblies that offer flexibility for upgrades or modifications. This forward-thinking approach allows for smoother integration and ensures that your solutions remain relevant as technology evolves.

When selecting cable assembly solutions for engineering projects, choosing a reliable supplier is paramount. According to recent market research by Grand View Research, the global cable assembly market is projected to reach $183.8 billion by 2025, growing at a CAGR of 6.6%. This growth underlines the increasing demand for high-quality cable assemblies in various sectors, including telecommunications, automotive, and industrial applications. A trustworthy supplier not only provides high-quality products but also embodies reliability in delivery, support, and overall service.

A critical factor in evaluating suppliers is their compliance with industry standards and certifications. Providers that meet international standards such as ISO 9001 ensure that their processes are aligned with best practices, minimizing the risk of defects and ensuring consistent performance. Additionally, assessing a supplier's manufacturing capabilities and quality control systems is essential. According to a study by Technavio, 43% of companies prioritize supplier reliability and quality when selecting cable assembly manufacturers. Engaging a supplier who emphasizes innovation and adheres to rigorous testing standards can enhance the success of your projects by mitigating risks associated with component failures.

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681