In the rapidly evolving landscape of electronics and connectivity, the importance of connector cable assemblies cannot be overstated. According to a recent market report by MarketsandMarkets, the global connector market is projected to reach $103.2 billion by 2026, growing at a CAGR of 5.6%. This surge highlights the increasing demand for efficient and customized solutions that enhance connectivity and data transfer across various industries, from telecommunications to automotive. Custom connector cable assemblies play a pivotal role in this growth, offering tailored solutions that meet specific project requirements while optimizing performance and reliability. As industries strive for greater efficiency and innovation, understanding how to leverage connector cable assemblies effectively becomes essential for success in any technical project.

Custom connector cable assemblies have become essential in modern projects, especially as industries push for greater efficiency and performance. These assemblies facilitate seamless connections between various components, ensuring reliable data transfer and minimizing signal loss. Recent innovations highlight the importance of these custom solutions, particularly in high-speed interconnects where understanding and controlling impedance is vital. With studies indicating that poor impedance control can lead to up to 30% signal degradation, the demand for tailored connector assemblies is on the rise.

Custom connector cable assemblies have become essential in modern projects, especially as industries push for greater efficiency and performance. These assemblies facilitate seamless connections between various components, ensuring reliable data transfer and minimizing signal loss. Recent innovations highlight the importance of these custom solutions, particularly in high-speed interconnects where understanding and controlling impedance is vital. With studies indicating that poor impedance control can lead to up to 30% signal degradation, the demand for tailored connector assemblies is on the rise.

The emergence of new technologies underlines the growing importance of custom connectors across various sectors. For instance, developments in e-bike technology showcase how customized solutions can enhance design and performance, driving competitive advantages. Moreover, the integration capabilities of custom connectors with enterprise platforms demonstrate their critical role in streamlining operations and enhancing user experiences. Data indicates that implementing such solutions can yield productivity gains of up to 25%. As industries continue to evolve, investing in custom connector cable assemblies will be crucial for maximizing efficiency and enabling innovation.

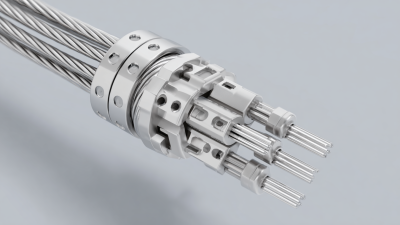

When designing custom connector cable assemblies, several key factors must be taken into account to maximize efficiency and performance. Firstly, it is essential to choose the right materials for both the cable and connectors. High-quality materials can significantly impact the durability and conductivity of the assembly. For instance, selecting the appropriate gauge wire can minimize resistance and enhance signal integrity, while connectors made from corrosion-resistant metals can improve longevity in various environments.

Another critical aspect is the design layout of the cable assembly itself. This includes considerations such as cable length, bend radius, and the arrangement of connectors. A well-planned layout can prevent signal loss, reduce electromagnetic interference, and allow for easier installation and maintenance. Additionally, ensuring that the assembly complies with relevant industry standards will enhance its reliability and safety. By paying attention to these details during the design phase, engineers can create custom connector cable assemblies that meet project requirements and perform optimally in their intended applications.

In the context of maximizing efficiency in custom connector cable assemblies, selecting the right materials and components is pivotal for both performance and sustainability. The advancement of technology has significantly altered how industries approach the design and production of these assemblies. Automation and innovative manufacturing processes now enable the incorporation of sustainable materials, which not only reduce environmental impact but also enhance product longevity. Utilizing advanced materials that meet efficiency standards while also being environmentally friendly supports the industry's push towards greener manufacturing practices.

As the market demands evolve, the need for adaptable and reliable connector solutions becomes increasingly important. Industries are now prioritizing the integration of sustainable practices in their operations, which includes sourcing materials that have a lower carbon footprint. This trend is further propelled by regulatory frameworks and consumer expectations for environmentally responsible products. In this ever-changing landscape, organizations must remain agile, continuously evaluating their material choices and production methods to align with both efficiency goals and sustainability objectives. The successful fusion of these elements positions businesses to thrive in a competitive market.

This bar chart illustrates the average efficiency ratings of various materials used in custom connector cable assemblies. The data highlights the performance metrics based on material types and their respective thermal and electrical conductivity, crucial for optimizing project outcomes.

In today's fast-paced production environment, optimizing manufacturing processes for high-quality cable assemblies is crucial for enhancing overall efficiency.

By employing lean manufacturing principles, organizations can reduce waste and streamline workflows, ensuring that each phase of production contributes to the final product. This approach not only minimizes delays but also enhances the quality of custom connector cable assemblies, meeting the specific requirements of various projects.

Integrating advanced technologies such as automation and real-time monitoring can further improve the manufacturing process.

Automation reduces human error and increases precision in cable assembly, while real-time monitoring allows manufacturers to track quality metrics throughout production. Investing in skilled personnel and continuous training in best practices also plays a vital role in achieving superior quality. By focusing on these key areas, businesses can not only maximize the efficiency of their manufacturing processes but also ensure that their cable assemblies consistently meet the highest standards of quality.

When working on custom connector cable assembly projects, troubleshooting common issues can significantly impact the overall project efficiency. According to recent industry reports, nearly 30% of delays in electronics assembly come from connector-related problems. These can range from improper connections to physical defects in cables. Understanding these challenges is essential for seamless integration into larger systems, such as robotic applications that require precision and reliability.

Tips: Always double-check the specifications of your connectors and ensure they align with the components of your project. Using standardized connectors can minimize compatibility issues, which often arise during robot assembly, as many engineers report compatibility as one of the top five challenges in robotics design.

Additionally, testing cables before full-scale production is crucial. Reports indicate that conducting rigorous pre-production testing can reduce failures by up to 40%. Implementing quality assurance processes not only saves time but can also significantly decrease costs in the long run, especially for projects where downtime can lead to substantial financial losses.

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681