In the rapidly evolving landscape of modern electronics, the significance of high-quality cable assembly connectors cannot be overstated. Recent industry reports indicate that the global market for cable assembly connectors is projected to reach approximately $83 billion by 2027, with a compound annual growth rate (CAGR) of 7.5% over the next five years. These connectors are pivotal in ensuring robust performance and reliability across a myriad of applications, from consumer electronics to industrial automation. As electronic devices become increasingly compact and sophisticated, the demand for reliable and efficient cable assembly connectors grows. High-quality connectors not only enhance the durability and longevity of electronic systems but also optimize signal integrity and minimize electromagnetic interference. Therefore, investing in superior cable assembly connectors is essential for manufacturers aiming to maximize performance and meet the stringent demands of today's technology-driven market.

Cable assembly connectors play a crucial role in enhancing the performance of modern electronics. As devices become increasingly compact and sophisticated, the demand for high-quality connectors has surged. According to a report by MarketsandMarkets, the global connector market is expected to reach $90 billion by 2025, growing at a CAGR of 5% from 2020. This growth underscores the vital contribution of cable assembly connectors in ensuring efficient signal transmission and minimizing interference, which are essential for the functionality of contemporary electronic devices.

In high-frequency applications, such as telecommunications and data transmission, the quality of connectors directly impacts overall system performance. For instance, research from Frost & Sullivan indicates that the improper selection of connectors can lead to a signal loss of up to 50%, significantly degrading the reliability of electronic communication. As modern electronics continue to evolve with innovations like 5G and IoT, the relevance of durable connectors capable of supporting high data rates becomes paramount. By investing in superior cable assembly connectors, manufacturers can achieve a competitive edge, enhancing the durability and performance of their products.

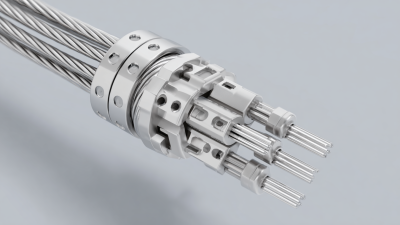

High-quality cable assembly connectors are crucial components in modern electronics, particularly in enhancing efficiency across various applications. These connectors must exhibit durability, high-speed performance, and compatibility to maximize data transmission rates and reliability in optical interconnects. The market for optical interconnects has been growing, driven by the increasing demand for high-speed data transfer in sectors such as telecommunications and data centers. Different product types—such as cable assemblies, connectors, optical transceivers, and silicon photonics—play a significant role in meeting this demand.

When selecting cable assembly connectors, it’s essential to consider their key features. For instance, connectors should provide excellent shielding against interference, robust locking mechanisms, and low insertion loss to ensure optimal performance. Investing in high-quality connectors can significantly reduce downtime and maintenance costs.

**Tips:** Always look for connectors that offer a higher number of cycles to reduce replacement frequency. Additionally, ensure they adhere to industry standards for quality assurance. Keep an eye on emerging technologies that can lead to advancements in connector design and material usage, as they often enhance performance and durability.

As digital connectivity evolves, the demand for high-quality cable assembly connectors has surged. Reports indicate that the global market for cable assembly connectors is projected to reach $65 billion by 2026, growing at a CAGR of 8.1% from 2021 to 2026. This growth is fueled by advancements in technologies such as 5G, IoT, and smart devices, which require robust and reliable connections. Consequently, manufacturers are investing in innovative design practices that enhance the performance and durability of cable assemblies.

One of the prominent trends shaping cable assembly design is the move toward miniaturization without compromising performance. As devices become smaller and more powerful, the connectors used in them must also adapt. For instance, the implementation of advanced materials and precision engineering has led to connectors that can operate at higher frequencies while maintaining signal integrity. According to a recent study by Research and Markets, the demand for high-frequency connectors is expected to grow significantly, reflecting the need for superior connectivity solutions that support emerging applications in telecommunications and consumer electronics. This not only boosts device performance but also enhances user experience in an increasingly interconnected world.

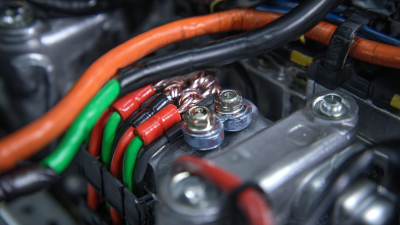

When selecting connectors for electronic applications, it is crucial to consider several factors to ensure optimal performance. Firstly, the specifications of the application, including voltage, current ratings, and environmental conditions, should guide the choice of connectors. Different applications may require connectors that are resistant to extreme temperatures, moisture, or mechanical stress, making it essential to analyze the operating conditions thoroughly.

Another vital consideration is compatibility with existing systems and components. The physical dimensions, pin configuration, and electrical characteristics must align with the overall design. Utilizing connectors that facilitate ease of installation and maintenance can enhance the efficiency of the electronic system. Furthermore, selecting high-quality materials, such as gold-plated contacts, can improve conductivity and reliability in data transmission, minimizing signal loss and extending the lifespan of the assembly.

Finally, manufacturers’ reputation and adherence to industry standards should not be overlooked. Trusted brands often provide connectors with certifications that guarantee performance and safety, ensuring that they meet the stringent requirements of modern electronics. By following these best practices, engineers can maximize the effectiveness of their cable assembly connectors, directly impacting the performance of their electronic devices.

The future of cable assemblies is rife with innovations that promise to significantly enhance the performance of modern electronics. According to a report by MarketsandMarkets, the global cable assembly market is projected to reach USD 215 billion by 2025, driven by the demand for high-performance electronic devices. These advancements include improvements in materials, such as the adoption of high-frequency, low-loss dielectric materials, which facilitate better signal integrity and reduced interference. This is particularly critical in applications involving high-speed data transmission, where even minor signal degradation can lead to substantial performance loss.

Innovative connector designs are also emerging, featuring enhanced durability and ease of use. For instance, advanced locking mechanisms and modular designs are being introduced to ensure reliable connections in harsh environments, which is essential for industries like automotive and aerospace. Furthermore, the integration of smart technologies and IoT capabilities into cable assemblies will revolutionize monitoring and diagnostics, leading to proactive maintenance and reduced downtime. As these technologies evolve, they will not only enhance the functionality of electronic devices but also ensure optimal performance across a variety of applications, from consumer electronics to industrial automation.

| Connector Type | Data Rate (Gbps) | Maximum Current (Amps) | Applications | Future Innovations |

|---|---|---|---|---|

| USB Type-C | 40 | 5 | Smartphones, Laptops | Enhanced Power Delivery, Data Encryption |

| HDMI 2.1 | 48 | 3 | TVs, Gaming Consoles | Dynamic HDR, 8K Video Support |

| Ethernet RJ45 | 10 | 1.5 | Networking, Data Centers | Support for PoE++, 25/40GBASE-T |

| Molex Connectors | Varies | Varies | Automotive, Industrial | Advanced Miniaturization, High Reliability |

| FPC Connectors | 6 | 3 | Smart Devices, Wearables | Flexible Designs, Miniaturization Trends |

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681