In the fast-evolving landscape of electric vehicle technology and renewable energy systems, the significance of battery cable assembly has never been more pronounced. According to a recent report by MarketsandMarkets, the global battery cable market is projected to reach USD 1.5 billion by 2025, reflecting an annual growth rate of 6.2%. This growth underscores the critical role that reliable battery connections play in ensuring optimal performance and longevity of energy storage solutions. However, common issues such as improper cable sizing, inadequate insulation, and poor connection quality can significantly hinder performance and lead to system failures.

As the demand for efficient and robust battery cable assembly continues to rise, addressing these challenges is essential for manufacturers and engineers aiming to deliver high-performing electrical systems that meet the stringent demands of modern applications. This blog will explore the prevalent issues in battery cable assembly and offer insights on how to overcome them, paving the way for enhanced efficiency and reliability.

Battery cable specifications are crucial in ensuring optimal performance in various applications, particularly in electric vehicles (EVs) and renewable energy systems. According to a report by the International Council on Clean Transportation, the demand for EVs is projected to increase significantly, necessitating the use of high-quality battery cables that can efficiently manage power transmission. The right specifications, including diameter, insulation type, and current carrying capacity, play a vital role in minimizing voltage drop and heat generation, which are critical for maintaining performance and safety.

Moreover, the American Wire Gauge (AWG) system is an established standard that helps determine the appropriate cable size for different applications. Cables that are too thin can lead to higher resistance, resulting in energy loss and potential overheating. Data from the National Renewable Energy Laboratory indicates that using cables that meet or exceed necessary specifications can enhance energy efficiency by up to 10%. Thus, adhering to specific battery cable requirements not only improves performance but also extends the lifespan of the entire battery system. Proper understanding and implementation of these specifications can ultimately lead to more reliable and effective energy solutions.

This chart illustrates the impact of different wire gauges on battery cable performance metrics, including current capacity, voltage drop, and temperature rise. Using the right specifications helps in overcoming common issues in battery cable assembly.

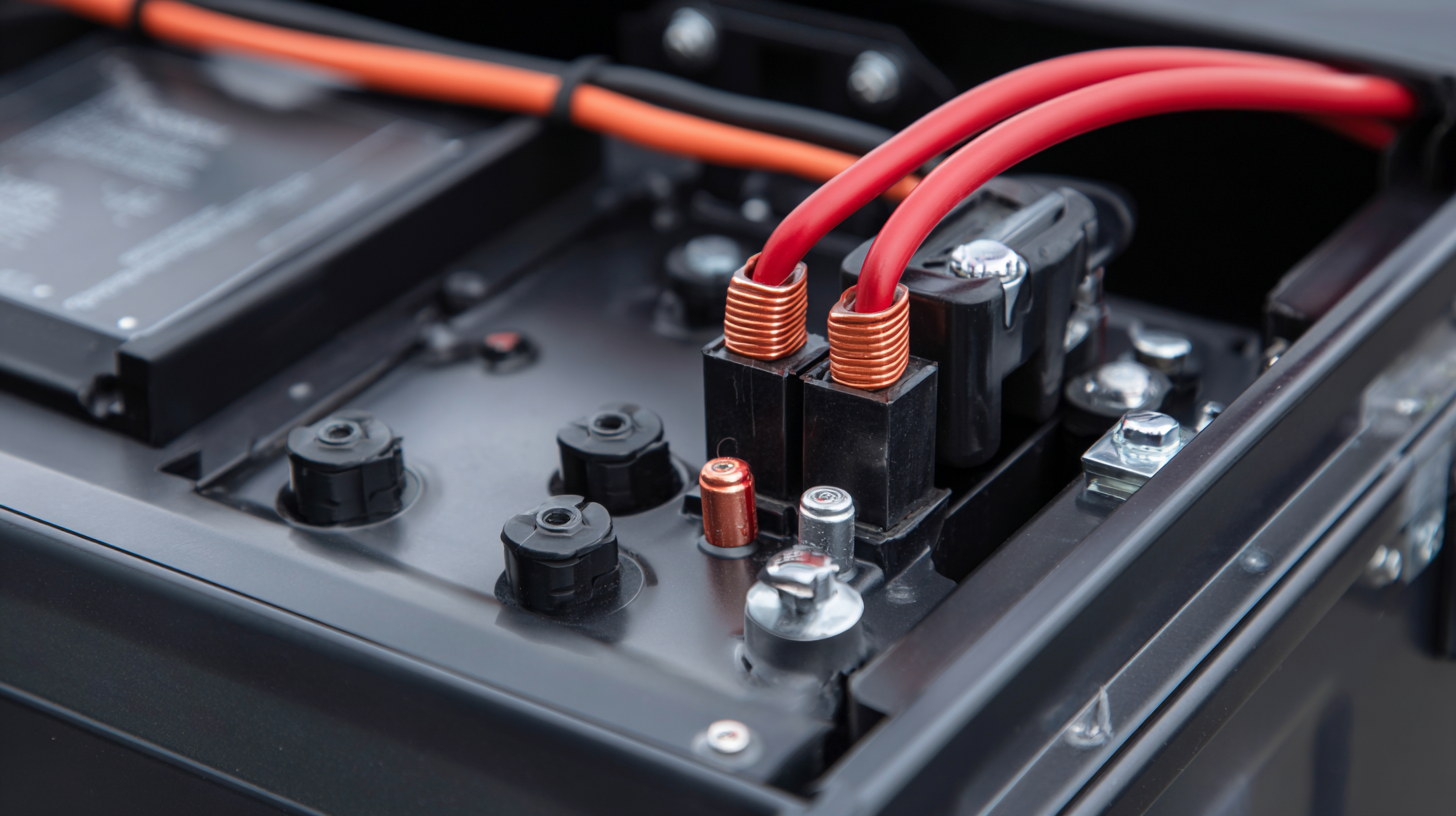

Effective thermal management is crucial for enhancing the longevity and performance of battery cables. Overheating can lead to accelerated wear, decreased conductivity, and potential safety hazards. According to a report from the International Energy Agency, temperature spikes can reduce battery lifespan by up to 30%. Implementing strategies for effective thermal management not only helps in maintaining optimal operating conditions but also improves overall efficiency.

One key factor influencing battery cable longevity is the choice of materials. High-quality, temperature-resistant materials can significantly reduce the risk of thermal degradation. Polyethylene and cross-linked polyethylene (XLPE) are recommended for insulation due to their excellent thermal stability. Moreover, regular inspections and maintaining proper connections can prevent overheating due to poor contact, a common issue highlighted in a study by the Society of Automotive Engineers.

Tips:

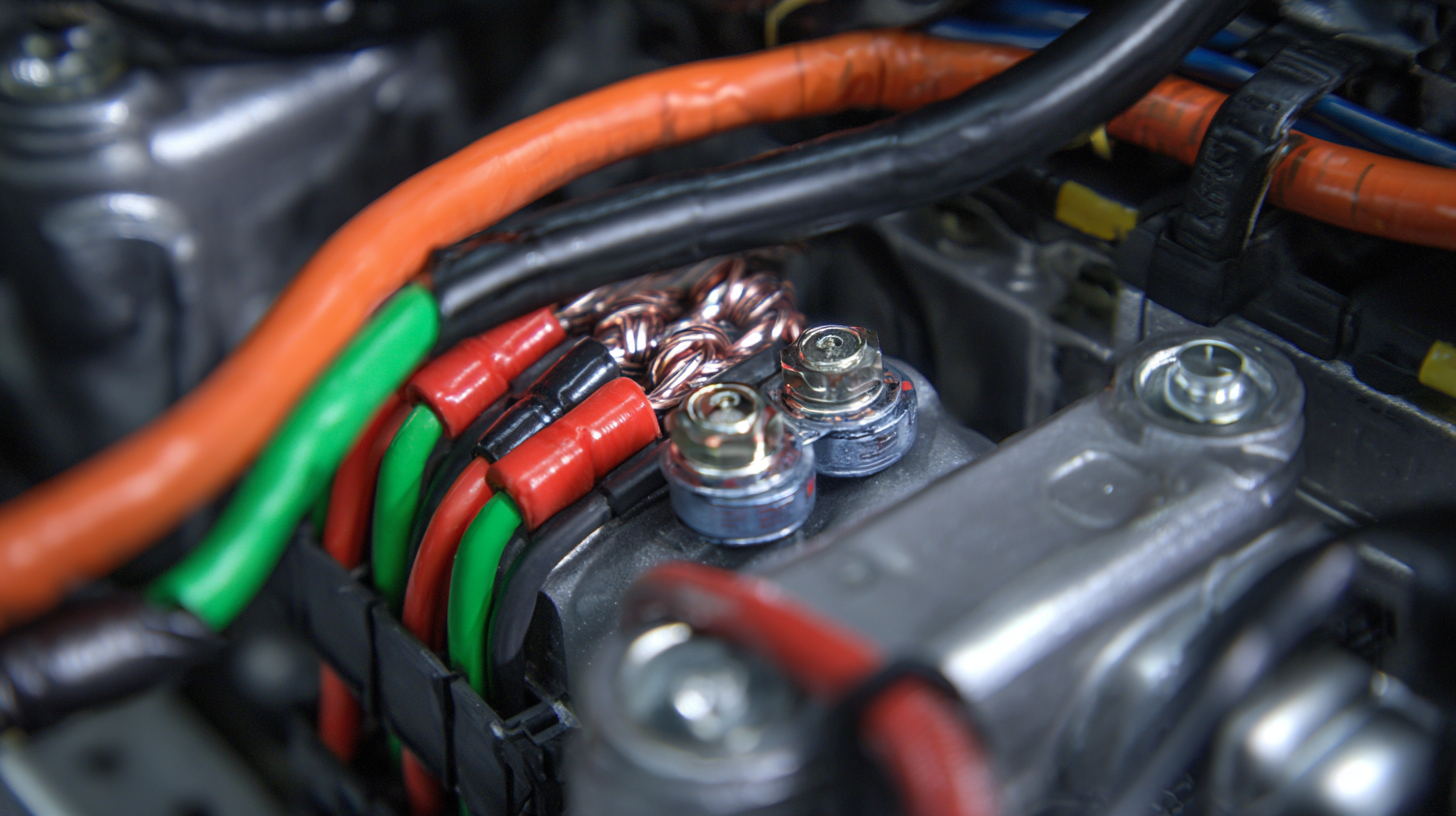

Battery cable assembly is a critical component in ensuring optimal performance and efficiency in various applications, especially in electric vehicles and renewable energy systems. However, there are common challenges that can arise during the assembly process, which can significantly impact overall efficiency. For instance, poor cable selection or improper crimping techniques can lead to increased resistance, heat generation, and ultimately energy losses. Additionally, inadequate insulation and protection can expose cables to environmental hazards, which may cause premature failure or reduced performance.

Battery cable assembly is a critical component in ensuring optimal performance and efficiency in various applications, especially in electric vehicles and renewable energy systems. However, there are common challenges that can arise during the assembly process, which can significantly impact overall efficiency. For instance, poor cable selection or improper crimping techniques can lead to increased resistance, heat generation, and ultimately energy losses. Additionally, inadequate insulation and protection can expose cables to environmental hazards, which may cause premature failure or reduced performance.

Another challenge lies in the improper routing and securing of cables. When cables are not neatly organized or securely fastened, they may experience mechanical stress during operation, leading to wear and potential damage. Furthermore, contamination during the assembly process, such as dirt or moisture, can compromise the integrity of connections and insulation, resulting in intermittent failures. Addressing these common issues through meticulous assembly practices, proper training, and rigorous quality control is essential for enhancing the efficiency and reliability of battery cable systems, ultimately contributing to better performance in the technologies that rely on them.

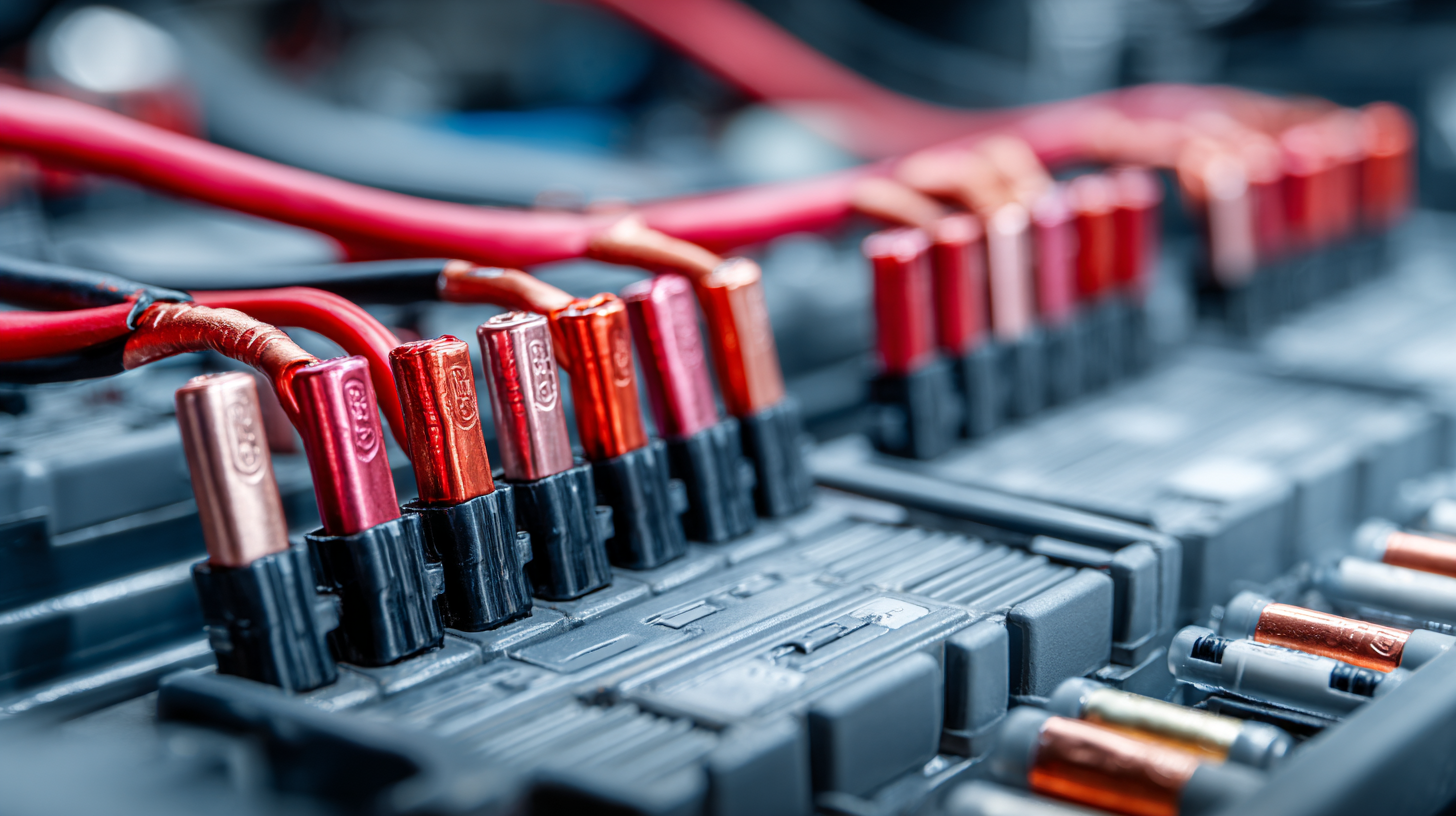

In the rapidly evolving landscape of battery cable assembly, industry standards and innovations play a crucial role in enhancing performance and reliability. As electric vehicle and renewable energy markets expand, manufacturers are increasingly adopting advanced techniques to optimize cable assembly. These innovations include the use of high-conductivity materials and improved design methodologies that ensure superior power transmission while minimizing resistance and heat generation.

Tip: When selecting materials for battery cable assemblies, always prioritize those that meet or exceed industry standards. Consider not just conductivity, but also factors like flexibility and environmental resilience. Using materials that are specifically designed for high-performance applications can significantly improve the lifespan and efficiency of the assembly.

Another significant trend is the implementation of automated assembly processes, which reduce human error and enhance consistency. Automation allows for precise connections and coatings that are vital for safety in high-current applications. As manufacturers embrace such technologies, the overall quality and performance of battery cables continue to improve.

Tip: Incorporate regular quality checks during the assembly process to catch potential issues early. This practice not only helps in maintaining compliance with industry standards but also ensures the reliability of the final product, which is critical in electric and hybrid vehicles.

In the world of battery cable assemblies, the choice of materials can significantly impact overall performance and reliability. High-quality materials, while often more expensive upfront, provide substantial long-term benefits that can outweigh their initial cost. For instance, premium copper conductors offer superior conductivity compared to lower-grade alternatives, reducing energy loss and heat generation during operation. This not only enhances the efficiency of the battery system but also contributes to prolonged lifespan, minimizing the need for frequent replacements and repairs.

Moreover, investing in robust insulation materials can prevent breakdowns and failures in harsh conditions, including extreme temperatures and environmental factors. High-quality insulation safeguards against abrasion and chemical exposure, ensuring that battery cables maintain integrity over time. While the initial investment may be higher, the reduction in maintenance costs, along with increased safety and performance, makes a compelling case for choosing superior materials in battery cable assembly. Ultimately, the cost-benefit analysis favors those who prioritize quality, as it fosters reliability and efficiency in battery systems.

| Issue | Impact on Performance | High-Quality Material Benefits | Estimated Cost Increase (%) | Long-Term Savings ($) |

|---|---|---|---|---|

| Corrosion | Increased resistance and heat generation | Improved conductivity and durability | 15% | $1,200 |

| Insulation Breakdown | Short circuits and power loss | Enhanced thermal stability and electrical insulation | 10% | $800 |

| Poor Termination | Connection failures and erratic performance | Reliable connections and reduced maintenance | 12% | $900 |

| Overheating | Reduced lifespan of cables and components | Higher current capacity and temperature resistance | 20% | $1,500 |

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681