Selecting the appropriate harness cable assembly for your specific needs can be a daunting task, given the vast array of options available in the market. A harness cable assembly is a critical component in many electronic and electrical systems, serving as the backbone that connects various components and ensures efficient operation. With the right assembly, you can enhance both the performance and reliability of your devices, while the wrong choice could lead to functionality issues or even safety hazards.

In this guide, we will explore the essential considerations to keep in mind when choosing a harness cable assembly. From understanding the specifications and materials needed to evaluating environmental factors and installation requirements, our top tips aim to empower you with the knowledge necessary to make an informed decision. Whether you are working on a project that requires custom configurations or simply need a standard solution, knowing how to navigate the selection process can significantly impact the success of your application. Join us as we delve into the top 10 tips that will help you identify the perfect harness cable assembly for your unique requirements.

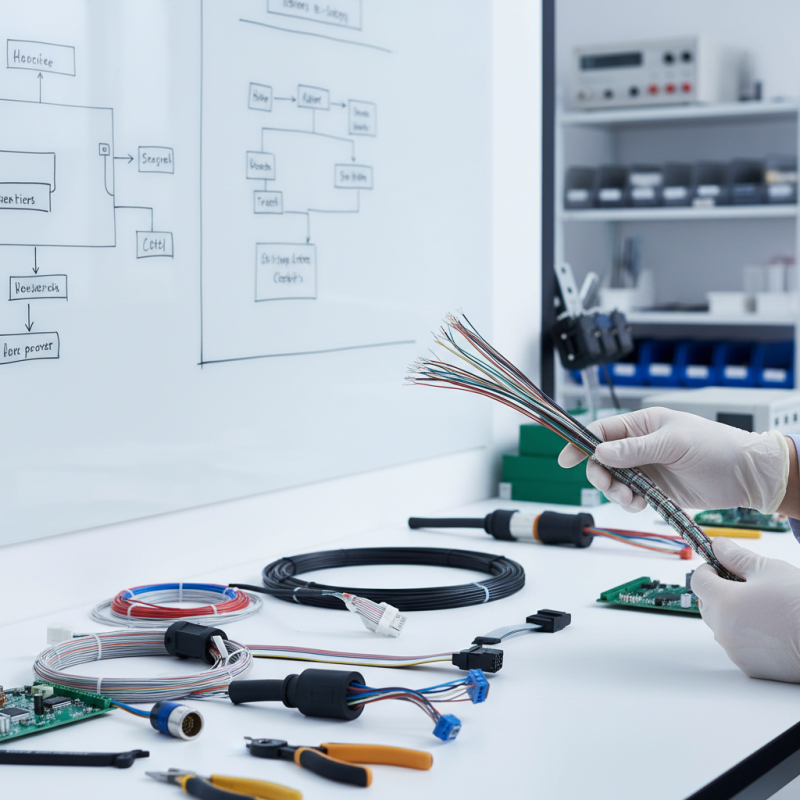

Harness cable assemblies are essential components that serve as the backbone of electrical systems, ensuring seamless connectivity and functionality. These assemblies consist of multiple wires bundled together, equipped with connectors, and designed for specific applications. Understanding the basics of harness cable assemblies begins with recognizing their key components: the wires, insulation, connectors, and the overall design. Each element plays a critical role in the assembly's performance, durability, and suitability for the intended environment.

When selecting a harness cable assembly, it is crucial to consider factors such as material compatibility, environmental exposure, and electrical requirements. Wires may differ in gauge depending on current-carrying needs, while the type of insulation affects both durability and flexibility. Connectors are also pivotal, influencing how easily the assembly can be integrated into existing systems and how well it withstands repeated use. An effective assembly not only meets technical specifications but also adheres to industry standards, guaranteeing reliability and safety in various applications.

When selecting a harness cable assembly, the first step is to clearly identify your specific requirements. Begin by analyzing your application environment and determining the conditions the assembly will be exposed to, such as temperature extremes, humidity levels, and potential for chemical exposure. Understanding these factors will help in choosing materials and designs that enhance durability and functionality. Additionally, consider the required electrical performance parameters, such as voltage, current capacity, and frequency. These factors are crucial in preventing failures and ensuring the reliability of the assembly.

Next, evaluate the physical layout of your application to ensure compatibility with your existing systems. This includes assessing the dimensions, weight constraints, and connector types that will be used. It’s important to have a thorough understanding of how the cable assembly will connect with other components to avoid misalignments or issues during installation. Furthermore, consider the potential for future scalability; will the system require upgrades or modifications down the line? This foresight can influence your choice, encouraging you to select a more versatile assembly that can adapt to changing needs.

When selecting a harness cable assembly, evaluating the material options is crucial for ensuring both durability and performance. Different materials offer varying levels of resistance to environmental factors such as heat, moisture, and abrasion. For example, polypropylene and PVC are commonly used for jackets due to their lightweight yet robust nature, providing excellent protection for the inner wiring against physical damage and wear. When considering extreme conditions, materials like silicone or TEFLON may be preferable due to their high thermal tolerance and chemical resistance, ensuring that the assembly functions efficiently over time.

Furthermore, the choice of conductor material significantly affects both durability and electrical performance. Copper, for instance, is widely recognized for its superior conductivity and flexibility, making it a popular choice among manufacturers. However, for situations where weight is a critical factor, aluminum can serve as a lightweight alternative, albeit with slightly lower conductivity. It's essential to match the material to the specific application needs, considering factors such as temperature range, exposure to solvents, and mechanical stress during operation. By thoroughly evaluating these material options, you can ensure the harness cable assembly meets the required standards for longevity and effectiveness in any given environment.

| Tip | Description | Material Options | Durability Rating | Performance Factors |

|---|---|---|---|---|

| 1 | Assess the Environment | PVC, TPE | Medium | Tension, Weather Resistance |

| 2 | Evaluate Cable Length | Copper, Aluminum | High | Signal Integrity, Flexibility |

| 3 | Check Connector Types | Plastic, Metal | High | Ease of Use, Safety |

| 4 | Consider Electrical Requirements | Silicone, PTFE | Very High | Current Rating, Insulation |

| 5 | Assess Mechanical Stress | Nylon, PVC | Medium | Wear Resistance, Fatigue Life |

| 6 | Review Regulatory Standards | Copper, Steel | High | Safety Compliance, Quality Assurance |

| 7 | Analyze Cost Efficiency | Aluminum, PVC | Medium | Lifecycle Cost, Maintenance |

| 8 | Seek Expert Advice | Various Combinations | Varies | Expertise, Reliability |

| 9 | Test for Compatibility | Silicone, TPE | High | Functional Testing, Performance |

| 10 | Plan for Future Needs | Continuous Improvement | Flexible | Adaptability, Scalability |

When selecting a harness cable assembly, it is crucial to consider the environmental impact of your choice. The materials used in cable assemblies can significantly affect their ecological footprint. Opting for eco-friendly materials, such as halogen-free insulation or recyclable components, can reduce harmful emissions and waste. This not only benefits the environment but also aligns with sustainability goals that are increasingly important for many industries. Moreover, understanding the life cycle of the cable assembly—from production and usage to disposal—can help you make an informed decision that minimizes environmental harm.

Additionally, the operational environment of the cable assembly plays a vital role in its longevity and performance. It’s essential to assess external factors such as temperature range, humidity, and exposure to chemicals or UV rays. Selecting a harness suited for specific conditions not only maximizes its efficiency but also prevents premature failure, which can lead to additional waste. By prioritizing environmental considerations in the selection process, you can support both the performance needs of your application and the sustainability initiatives that are essential for the planet's future.

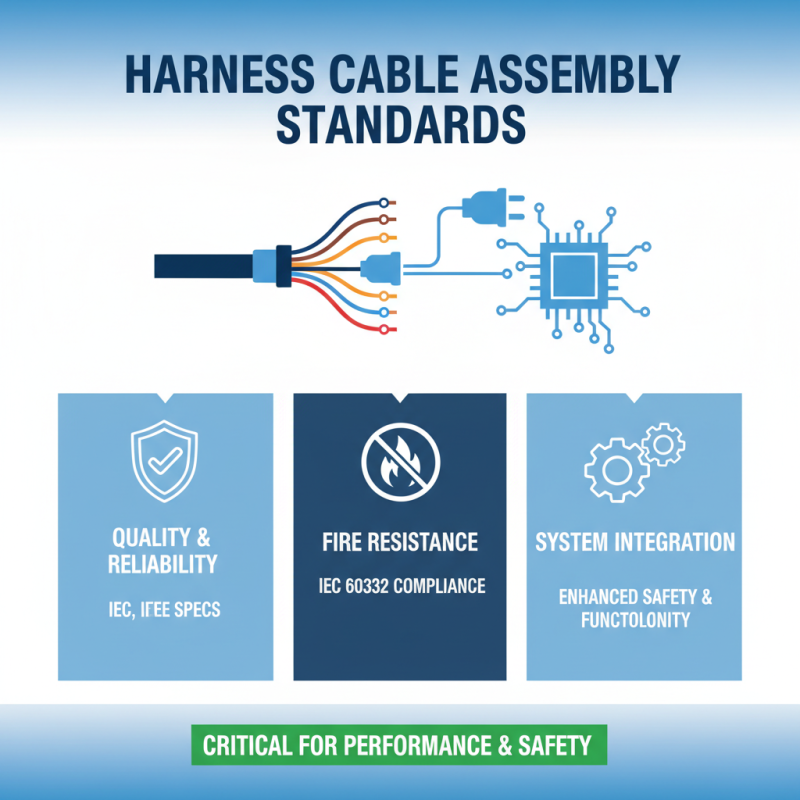

When selecting a harness cable assembly, compliance with industry standards is paramount to ensure quality and reliability. Leading organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) outline essential specifications that cable assemblies must meet. For instance, IEC 60332 defines the test methods for the fire-resistant performance of electrical cables, which is critical in applications where safety is a top priority. Adhering to these standards not only enhances product reliability but also ensures that the products can be safely integrated into various systems without compromising functionality.

One important consideration when choosing a harness cable assembly is to evaluate its compliance with relevant certifications, such as ISO 9001 for quality management systems. This can provide assurance that the manufacturing processes are continually improved and standardized. Moreover, reviewing the material certifications, such as RoHS compliance, ensures that the products are free from hazardous substances, aligning with global environmental regulations. It's advisable to request documentation that verifies compliance with these standards when evaluating suppliers.

When selecting the right cable assembly for your needs, consider the specific application requirements. For example, high-frequency applications may demand lower attenuation cables, assessing factors like capacitance and impedance is crucial. Additionally, understanding the environmental conditions where the assembly will operate, such as temperature extremes or exposure to chemicals, can guide you in choosing materials that resist such challenges. Emphasizing these industry standards and compliance measures will lead to informed purchasing decisions that meet both performance and safety criteria.

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681